31

Jan

We offer wheels in a wide variety of designs. The materials used determine the characteristics of the wheel and are therefore an important factor when considering the various applications.

The term „wheel” also incorporates further application criteria, such as the composition of the wheel center and the tread (tire). Materials for the axle include e.g. steel bushings and wheel bearings. Plain, roller or ball bearings can be fitted to meet specific requirements on the running properties of the wheel.

In the event industry, ball bearings or roller bearings are always recommended because of their low-noise operation. Wheels can also be fitted with additional accessories such as end caps, seals and thread guards.

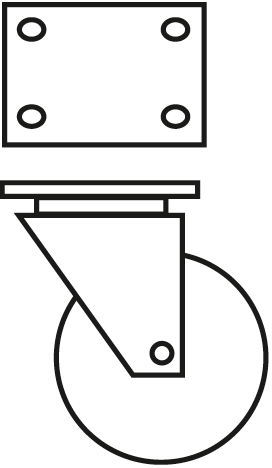

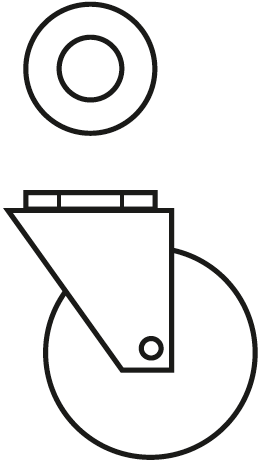

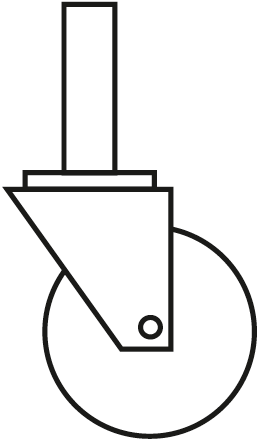

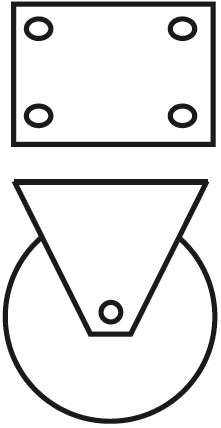

Castor bodies come in the following basic versions:

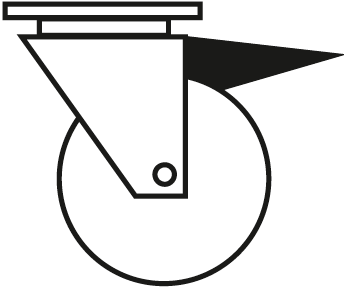

Swivel castor with top plate

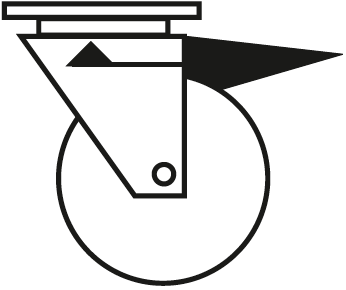

Swivel castor with rear hole

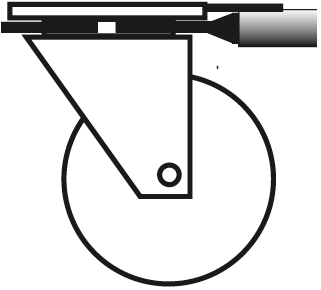

Swivel castor with pin

Heavy duty fixed castor

Braked castor – only the wheel is immobilized

Total lock – wheel and swivel function are immobilized

Direction lock – only immobilizes the steering direction

The load to be carried by the castors is made up of the empty weight of the handling equipment and the added load.

To determine the load capacity of a castor on equipment with four castors, it is necessary to divide the total load by three, since it can be assumed that only three castors will actually be bearing the load whenever the floor is not level.

The load capacities specified for our wheels and castors apply when the floor is level and smooth and for intermittent operations (alternating standing/ moving), and a maximum speed of 4 km/h at 20 °C room temperature. Since shock impacts (e.g. from edges or uneven floors) cannot always be avoi- ded, it is necessary to counteract any overloading of the castor by selecting an adequately large wheel diameter and elastic tire material (optimal: Adolan).

The swivel head of the mounting bracket is one of the central components where high-impact overloading is concerned. A high-quality, strong mounting bracket is more resistant to shock. When selecting wheels and/or castors, a reserve bearing capacity should always be included in the calculation.

The following types of resistance have an influence on the wheel movement:

The resistances listed above result from frictional forces that develop once the wheel or castor is moving. Adhesive or static friction will make any rolling body slow down and stop in its static condition. If this body is to be set in motion, the adhesive friction must first be overcome.

The force needed to do this is considerably higher than that required to keep the body moving at a constant speed. An additional force that has to be overcome is the rolling resistance, also referred to as drag. This always acts in opposition to the direction of movement of the wheel.

The greater the wheel diameter and the harder the tire material, the more the rolling resistance will be reduced.

A floor surface that is rough, soft and uneven provides the worst possible conditions for achieving a low rate of rolling resistance. The rolling resistance will however improve if the floor is hard, smooth and level.

The selection of the most suitable type of wheel or castor depends in particular on the required load capa- city, the floor, and the individual demands on running performance. In theaters, opera houses and event cen- ters, wheels and castors with Adolan tread and solid aluminum wheel center have proven to be ideal since they provide high load capacities with a minimum of noise.

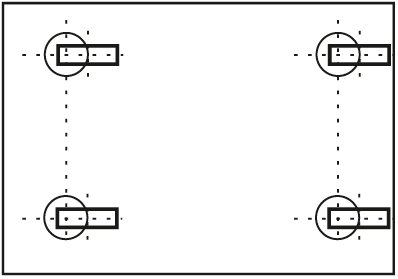

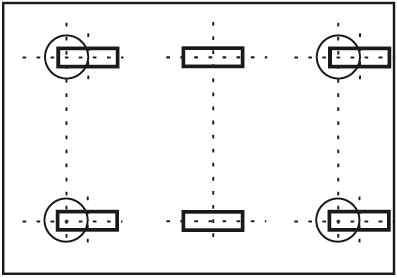

This is the most widely used arrangement

It warrants good running characteristics, both straight ahead and in curves.

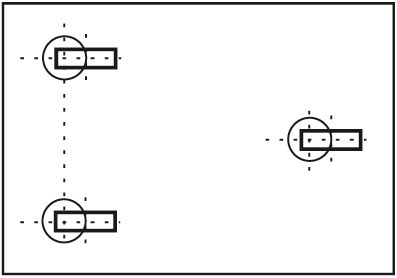

Application: Wherever space conditions are tight, e.g. in narrow corridors

Advantage: Can turn in all directions

Disadvantage: Difficult to steer

Application: For small loads

Advantage: Can turn in all directions

Disadvantage: Lack of stability

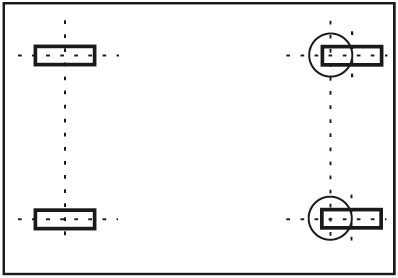

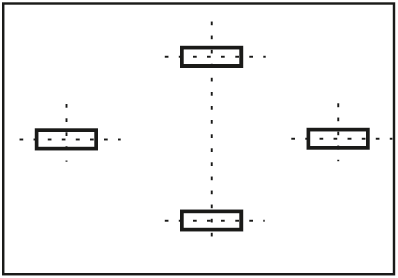

The middle pair of fixed castors for heavy loads have a slightly larger overall height.

Advantage: Easy to keep on course

Disadvantage: May tilt

Fixed castors for heavy loads have a slightly larger overall height.

Application: Wherever space conditions are tight; the flooring must be smooth and level.

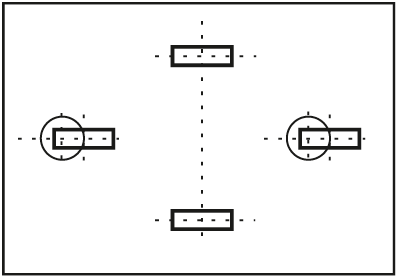

Advantage: Easy to maneuver.

Disadvantage: May tilt

Application: For heavy loads and long transport distances.

Advantage: Easy to steer because the swivel castors do not bear the full weight.

Disadvantage: Complex equipment.

Adolan is a viscoplastic polyurethane material with a very high dynamic load capacity. In combination with a solid aluminum center, Adolan is extremely wear-resistant, durable and absolutely nonmarking with a low permanent set rate.

One of the outstanding features of Adolan is that it can be mechanically processed by turning, milling, drilling, sawing, grinding and punching without any loss of quality and with high shore hardness rates. It is resistant to mineral oils and greases, benzine ozone and to hot air, oxygen and UV radiation.

Adolan is suitable for robust applications for which high load capacities and/or hard-wearing wheels and castors are required. Heat resistant (tire) from –20°C to +80°C; even up to 100°C in short-term use.

Adothan is a high-grade elastic polyurethane elastomer with a permanently bonded synthetic core. Its elasticity combined with its non-marking, non-tracing properties, and its resistance to diluted acids, leaches and mineral greases and oils make it ideal for use on problematic surfaces. Adothan is resistant to temperatures of between –20°C and +80°C, odourless, durable, hard-wearing, and it runs quietly.

This material is consequently very suitable even in sensitive areas such as kitchens and sanitary sectors.

Nicht alle Produkte sind in alle Länder lieferbar. Sie haben Fragen zur Lieferbarkeit außerhalb Deutschlands ? Bitte rufen Sie an +49-2331-69150-0 oder schreiben uns : mail@castinfo.de

Not all products are available in all countries. Do you have any questions about availability outside Germany? Please call +49-2331-69150-0 or write to us : mail@castinfo.de

Tous les produits ne sont pas disponibles dans tous les pays. Avez-vous des questions sur la disponibilité en dehors de l'Allemagne? Veuillez appeler le +49-2331-69150-0 ou nous écrire :